- Industry

Summary:

At FUCHS, we have launched a series of RENOCLEAN AIR products that, when combined with water, reduce dust at coal piles, ore pits, access roads and underground coal mines. This translates into cleaner air and cleaner environment.

Finding ways to control dust, especially particulate matter, is not only a major task for our society but also one of the FUCHS Group’s goals. In fact, this is already achievable for customers operating in the mining sector thanks to the RENOCLEAN AIR product series. Research is also underway in other industries.

Dust is everywhere – literally and figuratively. Because in addition to the fact that it can be felt with all the senses on a daily basis, it also appears as a concept in the public debate when talking about so-called “suspended dust.”

But where does something so elusive and ubiquitous even come from? Dust is mainly generated during combustion processes in motor vehicles, but not only. It also comes from many other sources: whether from power and heating plants, furnaces, heating systems, metal and steel production, during the handling of bulk goods, or being a byproduct of braking and tire wear.

It can also be formed naturally – as a result of soil erosion, forest fires and volcanic eruptions, or even when farming. Then chemical processes produce secondary particulates from gaseous precursors such as ammonia.

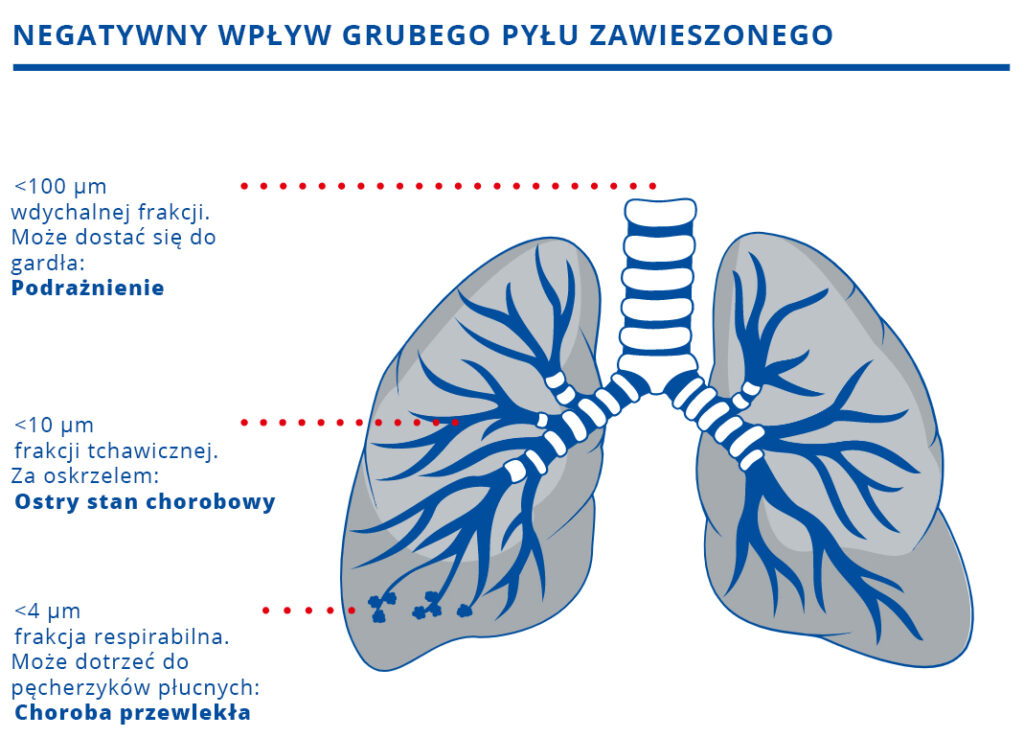

Particulate matter can be differentiated according to particle size. Ultimately, however, all types of particulate matter – whether coarse particles (2.5 to 10 microns in diameter), fine particles or very fine particles – have one thing in common: they are potentially harmful to human health.

Depending on their size, these particles can settle in the nasal cavities, bronchi or lungs and even enter the bloodstream. They negatively affect the cardiovascular system and can cause lung cancer.

They also harm the environment, acidifying lakes and streams, destroying forests or threatening the diversity of ecosystems.

So it should come as no surprise that various stakeholders are working to combat such a harmful byproduct. At FUCHS, we are also adding our ‘brick’ to reducing particulate matter by implementing specific environmental solutions.

The first Clean Air Act was enacted in the mid-1950s as a result of the 1952 smog disaster in London. It has been adapted and amended several times and is now the legal regulation for air pollution control in English-speaking countries.

For Europe, the EU Air Quality Directive 2008/50 / EC establishes limit values for particulate matter. The annual average threshold for “coarse” dust is 40 micrograms per cubic meter. The daily limit of 50 micrograms per cubic meter cannot be exceeded more than 35 times in a calendar year. The average annual limit for “fine” particulate matter is 25 grams per cubic meter. These values have been in effect since 2015.

The European Environment Agency (EEA) collects officially reported data on air quality in EU member states. The European Commission then uses this data to assess compliance with the set thresholds. In the US, the Environmental Protection Agency (EPA) performs this task. Areas that do not comply with the limits must develop air pollution control plans and action plans, including various emission reduction measures.

Sources of small particulate matter or PM10 emissions in Poland are: industry, vehicles, home heating systems and agriculture.

Unfortunately, in Poland, the aforementioned standards are exceeded, which resulted, for example, in a lawsuit brought against our country in the Court of Justice in Luxembourg. In December 2015, the European Commission reported that, since at least 2010, daily limit values for airborne particulate matter (PM10) had been consistently exceeded in 35 of Poland’s 46 air quality zones. In contrast, annual limit values were consistently exceeded in nine zones.

More recent data does not inspire optimism either. According to a 2018 WHO report, as many as 36 of the 50 most polluted cities in the EU are located in our country, with as many as 25 Polish cities in the top 30.

Sources of emissions of small particulate matter, or PM10 (i.e. particulate matter with a diameter of less than 10 microns) in Poland include industry, vehicles, home heating systems and agriculture.

European standards are strict but they must be met. Industrial companies therefore face considerable challenges.

At FUCHS, we support companies by providing them with products that meet the stringent requirements. That’s why we’ve been researching dust and particle control technologies for a long time and have launched innovative series such as RENOCLEAN AIR.

The products in this range help significantly reduce dust in mining and mineral handling operations, among others. The special additives which are mixed with water at low concentrations were developed to improve dust control spray systems used in mining areas and belt transfer points. When sprayed they serve as wetting agents for dust reduction in coal heaps, access roads, and coal cars.

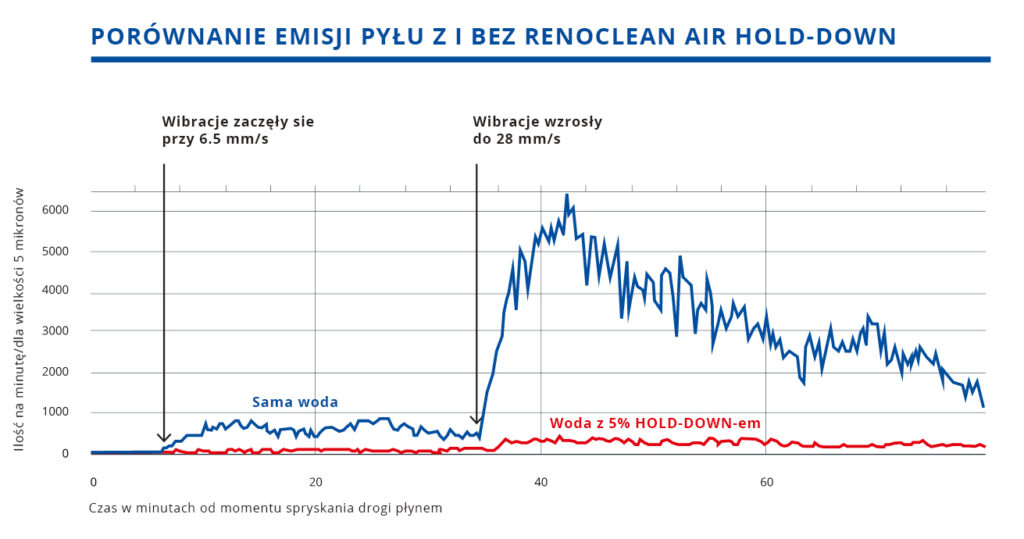

Adding 5% RENOCLEAN AIR HOLD-DOWN to the water generates significant improvements in dust suppression beyond what the water alone provides.

Some of the products in the series also work as road stabilizers on unpaved roads or can be used to stabilize coal piles and reduce emissions when transporting goods such as coal and ore. RENOCLEAN AIR has also been used in the UK mining industry since 2017.

We have many practical examples to prove the effectiveness of RENOCLEAN AIR products. This was the case of a concrete plant that suffered from very high dust emissions from natural roadways during traffic. FUCHS engineers took material samples from the roadway and then conducted laboratory tests to check the performance of RENOCLEAN AIR HOLD-DOWN dust suppression fluid. Compared to water as a dust control agent, RENOCLEAN AIR HOLD-DOWN perfectly bound particles, helped retain moisture and significantly reduced the amount of dust emitted.

In addition to reducing dust levels, the volume of water needed for dust control is significantly reduced. The solution saves fuel burned, driver time and reduces consumption of precious water. FUCHS calculations show that in some cases water consumption can be reduced by a factor of 2.5 and fuel cost savings of up to 61% can be achieved. In some countries, water is a very valuable resource and by using RENOCLEAN AIR products customers can conserve it for other purposes. By implementing RENOCLEAN AIR measures work safety can be significantly improved and financial savings can be achieved.

– says Paul Littley, executive director of Research and Development at FUCHS LUBRICANTS UK.

Research and implementation are ongoing. At FUCHS, we are currently conducting further field trials in the US, Australia, the UK and Poland. In addition to research dedicated to applications at customer locations, dust control technology plays the most important role at our company.

FUCHS has already filed a patent application for the dust control chamber it has developed. We simulate the formation of dust and particles in the smallest of spaces. In this way, wind speeds can be simulated, reaching nearly 100 kilometers per hour, as well as temperatures reaching 50 degrees Celsius and vibrations of the material substrate. An ultra-modern dust monitor checks the dust level in the air in real time and records it precisely. This technology enables FUCHS to develop and optimize formulations for a customer’s specific dust problems.

And these are just a selection of activities. Of the approximately 500 engineers and scientists who work for FUCHS in 25 different laboratories around the world, about 30 are actively working on dust control technology. Global research is coordinated and managed through a matrix structure of FUCHS research laboratories of which the UK laboratory is the leader. It is our dust control development center.

We know that air quality is a key issue and must be taken very seriously by the industry, both for the protection of employees and public space, meaning the company’s surroundings. With our products, customers are better able to comply with air pollution limits. We will continue to research and develop this technology

– convinces Littley.